Feature

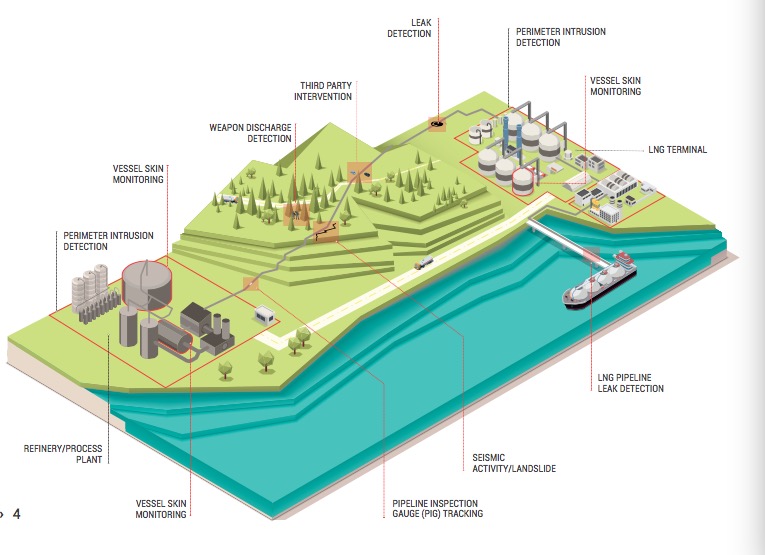

DAS monitoring for Third Party Intervention (TPI) detection before the event occurs, whether it is malicious (terrorist, product theft) or accidental (3rd party digging)

Precise, real-time and actionable information at all points on the pipeline to within 5m of the event

Proactive risk based maintenance using accurately measured real-time information

Smart condition monitoring leads to effective prediction and prevention of equipment failure

Leak detection using both Distributed Acoustic Sensors (DAS) and Distributed Temperature Sensors (DTS)

Utilize existing telecoms infrastructure along pipelines working closely with telecoms/SCADA installer

Smart software enables high probability of detection with a very low probability of false alarm activation

Benefits

› Prevention of product theft, improved safety, lower maintenance and lower repair costs

› Rapid and focused decision making which improves custodianship over pipeline thus reducing risk to reputation damage

› Optimization of planned maintenance program and reduction in unscheduled downtime

› Reduced downtime leading to improved return on investment and delayed capital spending

› Early detection of leaks can prevent environmental damage, avoid fines and risk to reputation

› Ease of installation lowering overall cost of ownership

› Complete coverage of remote assets with limited capital expenditure and ability to quickly react to any threats before they occur

› Third Party Intrusion (TPI) detection (intentional sabotage or unintentional digging/drilling in vicinity)

› Perimeter Intrusion Detection System (PIDS)

› Pipeline Inspection Gauge (PIG) tracking

› Condition monitoring of pipe and valves

› Seismic and landfall detection

› Pipeline leak detection both for liquid (hydrocarbon, water and chemical) and gas

› LNG terminal and pipeline security and integrity

› Vessel integrity (leak detection and skin monitoring)

Contact:Majestic Industrial

Phone:+86-18820077078

Email: info@majestics.cn

Add:Soho3Q , Guanghua Lu, Chaoyang District, Beijing, China